high quality sewage centrifugal pump

Latest articles

Quenching is defined as the introduction of a neutral fluid (usually water or steam) into the atmospheric side of the seal to prevent the formation of solids that may interfere with movement or be used for other purposes.

high quality sewage centrifugal pump...

high quality sewage centrifugal pump 【high quality sewage centrifugal pump】

Read MoreThe dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

high quality sewage centrifugal pump...

high quality sewage centrifugal pump 【high quality sewage centrifugal pump】

Read More2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

high quality sewage centrifugal pump...

high quality sewage centrifugal pump 【high quality sewage centrifugal pump】

Read MoreMill sump

high quality sewage centrifugal pump...

high quality sewage centrifugal pump 【high quality sewage centrifugal pump】

Read MoreSlurry Pump

high quality sewage centrifugal pump...

high quality sewage centrifugal pump 【high quality sewage centrifugal pump】

Read MoreSlurry Pump

high quality sewage centrifugal pump...

high quality sewage centrifugal pump 【high quality sewage centrifugal pump】

Read MoreTraditionally, centrifugal pumps are used to pump highly abrasive slurries. Centrifugal pumps use the force generated by the rotating impeller to impinge kinetic energy into the slurry.

high quality sewage centrifugal pump...

high quality sewage centrifugal pump 【high quality sewage centrifugal pump】

Read MoreWhat is the best seal arrangement for the application?

high quality sewage centrifugal pump...

high quality sewage centrifugal pump 【high quality sewage centrifugal pump】

Read MoreWorking principle

high quality sewage centrifugal pump...

high quality sewage centrifugal pump 【high quality sewage centrifugal pump】

Read MoreSlurry Pump

high quality sewage centrifugal pump...

high quality sewage centrifugal pump 【high quality sewage centrifugal pump】

Read More

Popular articles

- Many types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

- The size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

- Mill sump

- Slurry Pump

- Desire for higher efficiency than centrifugal pumps

- With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

Latest articles

-

The Company Adopts Advanced Computer Aided Engineering Software

-

If centrifugal, are the impellers of the right design and material?

-

Slurry Pump

-

The concentration of solids in the slurry - measured as a percentage of the total volume.

-

Horizontal pumps are the most commonly used type of slurry pump and therefore have the advantage of being easy to install or maintain, a wide range of flow parameters to choose from and a wide range of design materials to choose from. One of the advantages of vertical pumps, however, is the relatively small amount of floor space required for installation.

-

Selecting the right pump for slurries is critical to get the most bang for your buck. Basic pump components, such as the impeller size and design, material of construction, and discharge configurations must be considered to ensure the pump will hold up against the wear caused by an abrasive slurry. Slurry pumps are generally larger in size when compared to low-viscosity liquid pumps and usually require more horsepower to operate because they're less efficient. Bearings and shafts must be more rugged and rigid as well.

Links

- Despite its simplicity, black electrical insulation tape is a testament to the effectiveness of specialized tools designed for specific tasks. Its ability to insulate, secure, organize, and protect makes it an everyday hero in the world of electrical work. Whether you are a professional electrician or a DIY enthusiast, keeping a roll of this tape handy can mean the difference between safe operations and potential danger. So next time you reach for your toolkit, remember that the humble black electrical insulation tape may be simple in appearance but is mighty in purpose.

Overall, Flex Tape is a versatile and reliable product that can be a handy addition to any DIY toolkit. Whether you need to temporarily fix a leak, repair a broken object, or secure a heavy item in place, Flex Tape can get the job done quickly and effectively. Just remember to follow the instructions carefully and use it in the appropriate situations to ensure the best results.

Lighting and A/V Electrical Control Boxes

warehouse striping tape. This also helps to prevent bottlenecks and congestion in high traffic areas of the warehouse.

Rubber tape edge sealant: application, advantages and disadvantages

Here are the general steps on how to apply butyl sealant tape:

In addition to its weather resistance, 3M amalgamating tape also offers excellent electrical insulation properties. It can be used to seal and protect electrical connections from moisture and corrosion, ensuring safe and reliable operation in industrial and commercial settings.

3m amalgamating tape

The primary difference between electrical and duct tape is their composition and material. Electrical tape is made from plastic vinyl or PVC, giving it a smooth and stretchy texture. Electrical tape is heat resistant and designed specifically for safely insulating electrical wires and materials that conduct electricity.

If you love tapes like we do, then you know how important electrical tape is. Today, I want to talk about 3M Rubber Electrical Tapes. As experts in all kinds of tapes we are excited to share our knowledge and enthusiasm for these amazing tapes and the applications they can be used in.

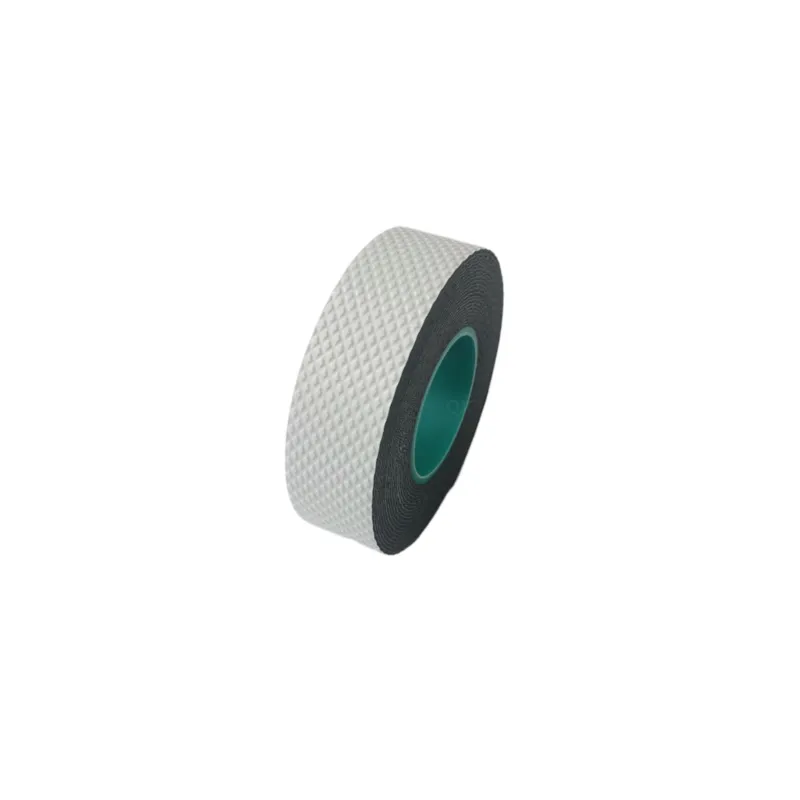

Window Glazing Double-Coated Polyethylene Foam Tape

Polyethylene Rubber Tape has several important characteristics:

Yes, 3M Rubber Electrical Tapes are engineered to repel moisture, making them perfect for outdoor applications. If wrapped properly, self-fusing rubber tapes can provide a watertight seal. To further protect against harsh environments, it's recommended to overwrap the rubber tape with durable vinyl electrical tape. These tapes are also built to withstand high temperatures, making them suitable for applications near motors, heat vents, or blast furnaces.

Silicone Rubber Tape is a versatile and resilient repair tool. It is made from high-quality silicone rubber, offering a wide range of applications. silicone rubber tape, in particular, stands out due to its exceptional quality and durability. This tape is designed to withstand various environmental conditions, making it an ideal choice for a wide array of repairs.